Latest facts and figures about cellcentric and NextGen fuel cell system for sustainable, economic heavy-duty transport

- Pioneer in Europe for development and manufacture of high-performance

fuel cell systems for heavy-duty applications with the aim of industrial-scale production with a high degree of vertical integration. - Fuel cell technology offers the best for two worlds - decarbonization of long-haul heavy-duty transport as well as expected TCO benchmark performance for fleet operators.

CO2-neutral fuel cell systems can make a significant contribution to decarbonizing heavy-duty long-distance transport and thus effectively protect the environment. For long-haul heavy-duty fleet operators - who literally keep global infrastructures running - TCO (total cost of ownership) is the decisive criterion. Powered by the latest cellcentric NextGen fuel cell system, Class 8 trucks can become an indispensable option for both - environmentally- and cost-conscious operators - thanks to their expected TCO benchmark performance.

NextGen fuel cell system - detailed deep dive at ACT Expo

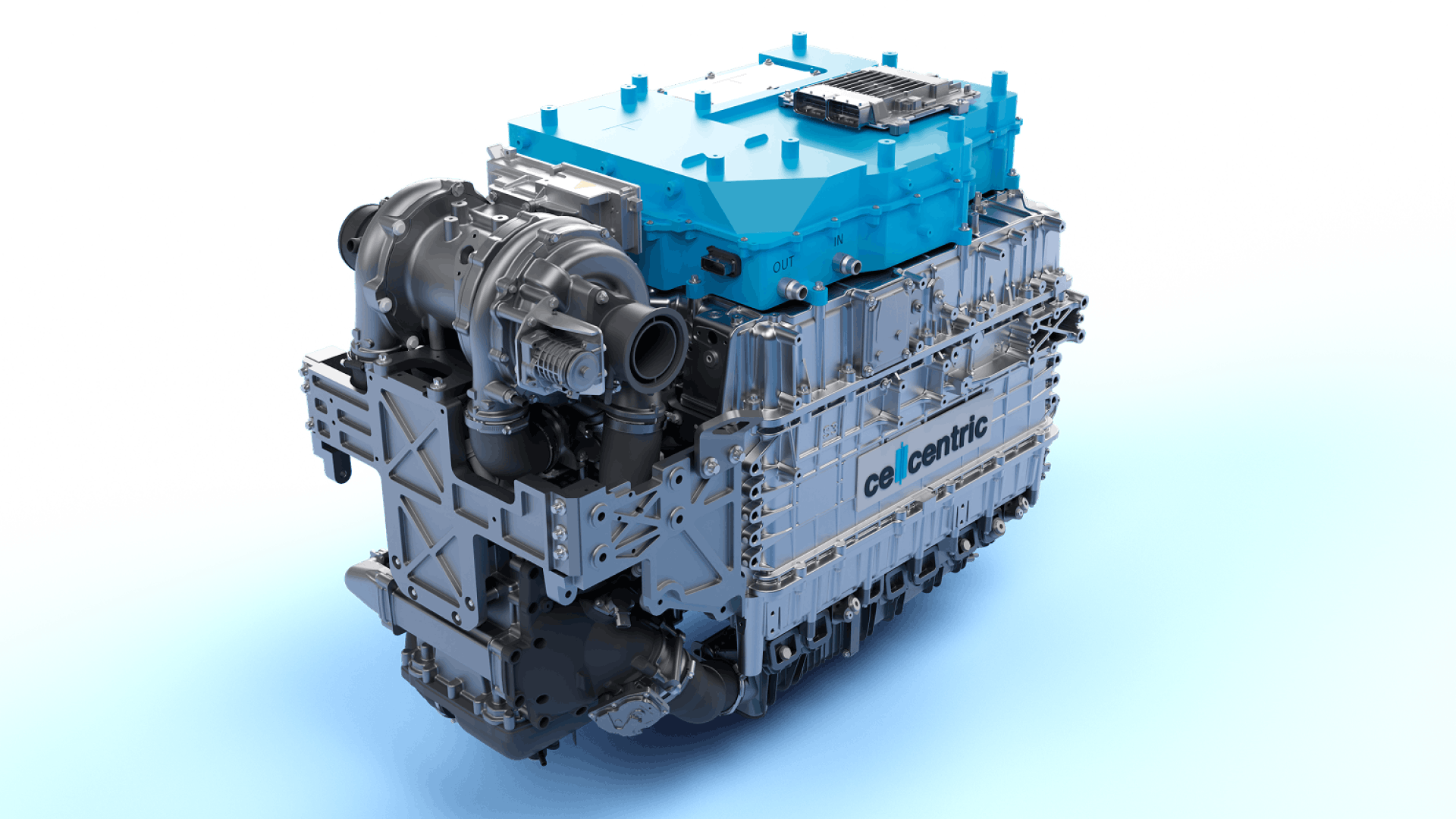

High power, low weight, long range, high flexibility, zero emissions - cellcentric will be presenting further details of its advanced NextGen fuel cell system for global heavy-duty road transport in North America at the ACT Expo 2025 in Anaheim (CA) from April 28 to 30 (booth 4937). A virtual model provides a preview of the dimensions and design of the game-changing new generation of heavy-duty fuel cell systems. With a total weight of approx. 400 kg, this new system is designed for conventional 13-liter diesel engine compartments and therefore easy to integrate into existing vehicle platforms. The new single-packaging fuel cell system will combine high efficiency and performance with market leading TCO. In addition, the system is characterized by higher operating temperatures and lower cooling requirements*.

NextGen fuel cell system:

Target performance figures (*vs. benchmark cellcentric fuel cell system BZA150)

- Single system package

- Up to 375 kW (more than 500 horsepower) continuous net power

- 20% less fuel consumption*

- 40% reduction of waste heat at 300 kW net power*

- 40% more power density*

- 40% reduction of complexity*

The bottom line is - with NextGen a fully loaded 40 ton heavy-duty truck is expected to need approx. 9.7 kg of hydrogen to travel 100 miles (= 10.2 miles per kg H2).

The improvements with NextGen are expected to lead to competitive driving characteristics for customers, especially on demanding routes in North America and Europe, e.g. on long inclines, at altitude and/or high ambient temperatures.

The fuel cell stack is main driver for increased system efficiency. Hence, the cellcentric NextGen uses 3 major levers to significantly improve fuel consumption on stack level:

- the increase of the active area of the stack,

- improved MEA (Membrane Electrode Assembly) efficiency by implementing new catalyst formulations,

- improved operating conditions and system design to fully use the benefit of cell technology (e.g. cathode pressure).

Need 300+ miles of range autonomy? Fuel cell electric trucks are the solution.

Heavy duty fuel cell systems enable highly efficient operation of heavy-duty trucks with ranges of more than 650 miles. Compared to other drive systems, fuel cell systems are lighter, allow a high payload, enable a longer range as well as rapid refilling, offer best possible flexibility comparable to diesel engines, and … are emission-free!

The weight of the complete fuel cell system with its hydrogen tank and its smaller battery is rather light, allowing a high payload. This is a major factor for customers.

The range of heavy-duty fuel cell hydrogen trucks is comparable to diesel trucks - depending on the capacity of the hydrogen tanks, the hydrogen used (>700 bar or liquid hydrogen (LH2)) and the efficiency of the fuel cell system. A clear advantage in flexibility.

Refilling at hydrogen refueling stations takes a comparable amount of time as refilling conventional trucks with diesel.

No emission - only emitting water vapor. When hydrogen is used to power a fuel cell, the only by products are water vapor and heat - no pollutants or greenhouse gases.

In addition, fuel cell systems are also suitable for comparable long-haul and heavy-duty applications such as coaches, mining vehicles, rail, and stationary power generation.

Successful real-world tests

cellcentric’s fuel cell technology has matured over 30 years, giving the company extensive practical experience in the automotive sector.

Daimler Truck AG and Volvo Group - 50:50 shareholders in cellcentric - successfully integrate cellcentric’s current BZA150 generation of fuel cell system into their prototype trucks. As a result, on-road testing provides valuable insights into performance and further development. With both shareholders cellcentric has impressively demonstrated that its fuel cell systems work reliable and efficient even under the toughest conditions - with high-altitude testing at Brenner Pass between Austria and Italy, and intensive winter testing at the Simplon Pass in Switzerland as well as at the arctic circle in Scandinavia.

Moreover, the #HydrogenRecordRun is an impressive example for fuel efficiency and range of a fully loaded 40 ton truck: In 2023 a Mercedes-Benz GenH2 Truck powered by two BZA150 fuel cells achieved a range of 1,047 kilometers on public roads with one filling of 80 kg of liquid H2.

Ramping up towards highly efficient large-scale production

Current production of BZA150 fuel cell systems in cellcentric's first “All under one roof” factory near Stuttgart, Germany, is a milestone towards reaching CO2-neutral and economic mobility in heavy-duty transport of tomorrow, utilizing highly efficient industrial-grade production processes. Same time, advanced engineering activities at cellcentric provide the basis for game changing further product improvements in future projects.

Furthermore, the industrialized pilot production marks another step towards the build-up of Europe's largest fuel cell production facility and further home of our advanced NextGen fuel cell system - the KLIMA|WERK factory in Weilheim, Southern Germany - which is planned by the end of the decade.

This is being done in order to scale the cellcentric production and to market the high-performance fuel cell systems worldwide to a wide range of manufacturers of heavy-duty trucks as well as of various other long-haul and heavy-duty applications.

cellcentric and its shareholders fully committed to advanced fuel cell technology

cellcentric and its shareholders, Daimler Truck and Volvo Group, are convinced that hydrogen and fuel cells are the solution for decarbonizing long-haul heavy-duty transport with Class 8 trucks and various other applications. As a Daimler Truck and Volvo Group subsidiary, cellcentric is robustly positioned to withstand market fluctuations. That’s why cellcentric is forging ahead with technological development. The practical experience with vehicle fleets from Daimler Truck and Volvo Group underlines cellcentric’s credibility.

cellcentric’s belief in advanced fuel cell technology remains. cellcentric continues to work with full effort on the decarbonization and the economic efficiency of long-haul heavy-duty transport.

About cellcentric

cellcentric develops, produces, and markets fuel cell systems for use in heavy-duty commercial vehicles as the focus as well as offroad applications. cellcentric is a joint venture founded in 2021 between Daimler Truck AG and the Volvo Group. The company utilizes the know-how and extensive experience gained from decades of developing fuel cell systems by its predecessor companies. cellcentric’s goal is to become a leading global manufacturer of fuel cells and thus making a contribution to climate-neutral and sustainable transportation by 2050. More than 560 highly qualified employees are driving our state-of-the-art fuel cell technology forward. They work in interdisciplinary teams at our sites in Nabern, Stuttgart-Untertuerkheim, Esslingen (Germany) and Burnaby (Canada). Roughly 700 individual intellectual property rights were filed, underline the company’s leading role in technological development.

Press contact

+49 (0)175 5337198

christian.kleinert@cellcentric.net